Total Quality

Delivering quality products

Our Commitment to Total Quality

Founded in 1987 as Knight and Counts, Inc. T/A Intercon, the company began developing partnerships with customers through the implementation of the Total Quality principles for perpetual improvement. The business grew by meeting the demand for wire harnesses and cable assemblies built to customer specifications.

Since that time, the company changed its name to INTERCON, INC. The company achieved ISO 9002 certification in April of 1998, and re-certification to the ISO 9001:2008 standard in October of 2010.

A highlight in Intercon Inc.’s history and qualification as an industry leader is its service as a member of the original group that developed the standard by which the cable and wire harness assembly industry is guided. Beginning in the late 1990’s, IPC/WHMA-A-620 formed a joint working group resulting in the January 2002 publication of the Standard entitled Requirements and Acceptance for Cable and Wire Harness Assemblies. One IPC-certified trainer is currently on staff, and all technicians are trained to up to 8 modules.

Now, after many years of quality-focused practices and a responsive system for continual improvement in place, Intercon, Inc. operates with consistent success and continues to grow, year after year.

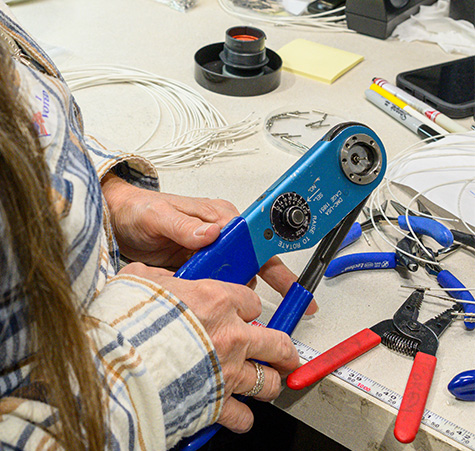

Intercon, Inc. has carved its niche by providing high-quality, short-run products in rapid turnaround time. We pride ourselves on the capability to build Over-molded, Discrete Wire Harnesses, Radio Frequency (RF) Cable Assemblies, Fiber Optic Cable Assemblies, Flat, and Conduit cables to customer specifications.

Intercon's Quality Policy

Our proactive strategic direction is meeting challenges, requirements, and quality objectives today and in the future by:

Connecting you to Quality through a commitment to:

- Continual Improvement

- Ongoing Education

- Teamwork

- Outstanding Service

……….Always!

Total Quality Activities

- Meet customer requirements

- Reduce development cycle times

- Timely demand flow manufacturing

- Improvement Teams

- Reduce product and service cost

- Continual training systems

Our Certifications & Affiliations

An IPC/WHMA-A-620 Certified Company

More About the IPC/WHMA-A-620 Certification

- The Wiring Harness Manufacturer’s Association (WHMA) and IPC teamed up to develop IPC/WHMA-A-620- the first industry-consensus quality standards for wiring harnesses and cable assemblies.

- Intercon provides continual employee education and certification to the IPC/WHMA-A-620 standard via an in-house Certified IPC Trainer.

- Employee training covers a wide range of subjects including wire and cable preparation, soldering, crimp termination, insulation displacement connector termination, ultrasonic welding, splicing, connectorization, molding, potting, labeling/marking, coax/twinax cable assemblies, wrapping/lacing/harnessing, shielding, wire-wrap terminations, and electrical testing requirements.

ITAR Registration

Intercon Inc. is registered with the US Dept. of State under the International Traffic in Arms Regulations (ITAR); and the US/Canada Joint Certification Office for Military Critical Technical Data Agreement (DD2345)

Testing Capabilities

Intercon possesses a wide range of automated and manual test equipment. Our experienced Quality Assurance technicians perform testing to your drawing requirements using calibrated equipment traceable to N.I.S.T. standards.

Our testing capabilities include:

- Continuity (pinout verification)

- Open circuits

- Short circuits

- Connection resistance

- Low voltage insulation resistance (IR)

- High voltage insulation resistance (IR)

- Dielectric withstanding voltage (DWV)

- Continuity of protective bonding circuit

- Component testing such as resistors, diodes, and capacitors

- Network analyzer testing of RF / coaxial cable assemblies (VSWR, insertion loss, and return loss from 10 MHz - 18 GHz)

- Cable analyzer testing of Cat 5 / 5e / 6 / 6a network cables

- Submersion/ingress testing